Pulling off DIY projects like this is what makes everything worth it. When you can produce something that is so dirt cheap and yet so effective at its purpose, it just makes you feel all warm and fuzzy inside. In this project, I'll show you how to make a weight bench that is strong and incredibly cheap. This is what DIY is all about.

Cost: less than $50

Project Time: 1 day

Difficulty: You have to cut 2x4s and plywood. You have to operate a drill. For the pad you have to cut fabric and use a manual powered staple gun. In other words, not hard at all.

Tools Needed:- Drill

- Saw (for cutting wood) - miter saw is best for cutting 2x4s, but you need something for long straight cuts in plywood as well (I used a normal handsaw)

- Staple Gun - just a manual powered one, you don't need an air compressor or anything fancy like that.

Materials Needed:- 2x4 Studs - at 8 feet long each, you'll need 5

- 4 Elevator Bolts (at least 1 1/2 inches long) - click here for picture

- 4 Wingnuts to fit the elevator bolts.

- Foam padding

- Fabric of your choice (vinyl, leather, auto or furniture upholstery)

- 2 1/2 inch decking screws (T-25 star head is my favorite)

- Wood glue

- Gorilla glue, or other similar metal/wood adhesive

- Staples for your staple gun (check your gun for proper size)

|

| The only person this won't be strong enough for is Bruce Banner. |

Shopping for a weight bench can be difficult. And by difficult I mean expensive. And just to be clear, whenever I use the phrase "weight bench" I mean a strong one that can be used to Bench Press. The problem you'll run into when buying these is that the reasonably priced ones are not rated to hold much weight. You'll see figures like "300 lbs." But when you consider that the bench has to hold your body as well, 300 lbs. is not much. If you weigh a measly 150 lbs. when you start, and bench press 150 lbs. That's your 300 lbs. right there. This is novice level lifting.

Once you turn into a real lifter after a few years of training, you'll probably weigh closer to 200 lbs. yourself and be benching near 300 lbs. Now that's 500 lbs. and all those affordable weight benches are now too weak for your purposes. But when you start pricing quality benches that are rated for this type of serious lifting, you are going to have to pay hundreds of dollars for them. This is unacceptable by Homemade Strength standards.

The fact of the matter is you can build your own weight bench that can support a ton of weight, I literally mean a ton, that's not slang. You'll never be able to bench press even half a ton so basically what I'm telling you is that you can build a bench that will be many times stronger than you need it to be. And you can do it for less than $50.

A proper weight bench is 17 inches tall, pad included. This bench will have a plywood base that is 3/8 inch thick. It will also have a plywood top, and the removable padding has a plywood base. The total thickness of all the plywood will add up to just over an inch. The pad itself is going to be about 1/2 inch when compressed. If your pad differs from this then adjust accordingly. However, it's better to make your bench too tall rather than too short. So we're going to cut our 2x4s into 15 1/2 inch segments. To start, we will cut sixteen pieces of 2x4, each being 15 and 1/2 inches long. If you have a miter saw or at least a power saw that can handle the job (circular saw, etc.) you will enjoy the process. If you do not, this will be the first wave of a lot of hard labor cutting by hand. Thankfully, I have a miter saw.

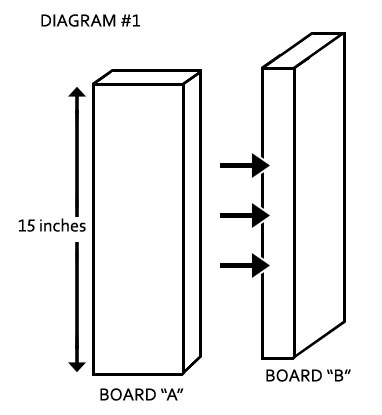

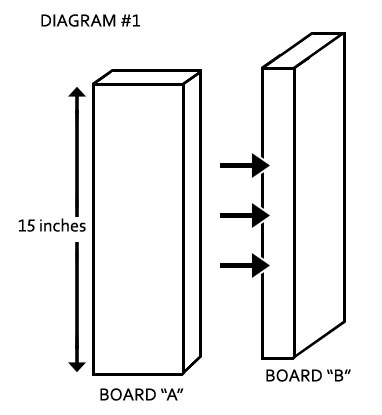

With sixteen boards cut to the length of 15 and 1/2 inches, we're ready to start assembling the top legs. These legs are like miniature I-beams made of three 2x4s each. It's important that you follow my directions of assembly. First step is to make a "T" out of two pieces (see diagram #1).

Mark and drill three holes through the top of the T (Board A). These three holes should be towards the middle of that 2x4, not towards the ends (see diagram #2). Read ahead if you have to, to gain more understanding of what we're doing and why. Drill all the way through Board A so that your bit goes into Board B. Then deepen the holes on Board B to prevent splitting when you put your screws in.

Slather some wood glue along the face where the boards will touch each other. Now drive three screws into the pre drilled holes. Wipe the excess glue off and you now have one "T" piece. Repeat this procedure and make a second "T" piece.

Now we will cut the 2x4 runners that span the length of the bench. We need two. I made mine 43 inches long. I'm 5 feet 10 inches tall and this gives me plenty of room on the bench. Just make sure your bench is long enough to accommodate you from the bottom of your ass to the top of your head. If you have at least that much room, you're good to go. Whatever measurement you choose, cut two 2x4 studs to this length.

Before we attach these, we have to make holes in our top legs (T pieces) to fasten them to the runners (see diagram #3). We will drill four holes in our "T" piece; two on top, two on bottom. I recommend that you drill from the top of the T downward, as shown in diagram #3. If you drill from the bottom up, Board B will get in the way. This is how we will have to drive our screws (unavoidable) but in order to make straight holes drill from the top.

|

| Aren't diagrams helpful? |

But before we drill, we have to measure. Take one of your T pieces and measure 2 inches from the end of Board A and mark a line. Now measure 4 inches from the same end and mark a line. Now repeat these steps for the other end of Board A. You have divided the ends of your board into two sections. We'll call them "top box" and "bottom box." For this T piece choose a box, it doesn't matter which so I'll just pick "top box." Drill two holes in the top box. One centered on each side of Board B. (diagram #3). Do the same for the other end of your T piece. So this is your "top box" T piece.

Now take your other T piece and do the same thing. But this time, drill your holes in the "bottom box". The reason this is important is because these T peices will both be screwing into the same middle board and we need to make sure that you get all four screws into a small space without hitting each other. In other words, the screws on the top box board will be higher than the ones from the low box board. Marking is key to avoiding conflict when it's time to put it all together.

With four holes drilled in your T pieces, we can now attach our long runners. We're going to start with the bottom runner. The best way to mark this runner is to drive screws into your predrilled holes on the bottom of your T piece. Have them sticking out the back of the T piece just a little bit. Now, line up the T piece with the bottom runner as shown in diagram #4. The left side of your runner board should be in line with the left side of your T piece.

Use a level to ensure you're T, which is a leg of the bench, is straight up and down. Now just press the T and the runner together. Since the screw tips were slightly through the T piece they will poke into the runner board and mark it. Now you can drill on those marks, just a bit (not all the way through. Predrilling like this ensures that everything goes in the way you want it and the wood will not split. Slather the point where the boards will contact each other with wood glue. Drive in your two screws. At this point you should have one long runner on the bottom, attached to one T piece.

THE IMPORTANT BOARD STEPThis is a significant step, we're going to label this "The Important Board Step" so that you can repeat it later when I tell you to. Grab two 15 1/2 inch boards. Just like you did with the T piece, measure 2 inches from the end of the board and mark a line, then measure 4 inches and mark a line. Do that on both ends of the board. And do that for both boards. Designate one board as "top box" the other as "bottom box". Drill two holes within the proper "box" on each end of the board. Again repeat that for both boards. So each board should have four holes in it, two at one end and two at the other. And one board should have said holes in the top boxes and the other in the bottom boxes.

Take one of these boards and, just like you did with the T piece, glue it and screw it to the other end (foot end) of the bottom riser, which is already attached to one T piece at the head end.

Now repeat the procedure with the top runner. Secure it to the top of the T piece at one end and the single 2x4 at the bottom. Again use your level to make sure your legs are straight and your runner is straight as well. We're building a flat bench, not an incline or decline bench, after all. Now you should have a frame that looks as it does in diagram # 4-B

To complete this side we need two more of those 15 1/2 inch studs. We're going to cap off our T and make it an I. Just like we did when making the T, put three holes along the length of the board, in the center as shown. Slather the contact point with wood glue and drive your three screws. Do the same exact thing with your single 2x4 at the foot, now making it a double 2x4 (in essence a 4x4). This is shown in diagram #5.

|

| Not to scale. |

From here, go back up the page, to the start, and read the directions again, this time doing it on the other side of the runners. Take the T piece that you've already made and attach it to the other side of the runners. Then take the single board you've already made for the foot of the bench and attach that to the other side of the runners. Then turn the T to an I and the single board to a double at the foot. You've now used up ten of our sixteen lengths of wood. The next step is to overkill reinforce this sucka.

The following picture will do more than words can to instruct you. It's quite straightforward, now that you've got some experience, we're not doing anything different than we've already done. We're putting three boards on each side, towards the head of the bench, where the weight and force will be when you bench press. This is where "The Important Board Step" comes in. We need 3 more pairs of boards. They have to match each other. Meaning 3 have to be "top box" and 3 have to be "bottom box". Basically just repeat the "Important Board Step" three times and you'll have three matching pairs. Secure them as the picture shows, three on each side, covering the top half of the bench (near the head).

|

| Two is better than one, and Twelve is better than two. |

No less than 12 supporting beams would have to utterly fail under the load in order for this bench to break. The rating for each beam is more than a ton. Since the average human would be absolutely ecstatic if they could manage even 1/4 that amount, I think we can safely say this bench is well beyond the strength of what you or I would ever need.

The frame of this thing is now complete. The next step is to put plywood on the bottom. The easiest way to do it is to simply put the frame onto your piece of plywood and trace around the frame. As you can see from the picture, I put a piece of plywood under the four 2x4s at the foot of the bench. I then put another piece under the six supports in the middle of the bench. Then another larger piece around the "I beam" legs at the head of the bench.

|

| You can click these pictures to enlarge them, didn't you know? |

This larger piece isn't a precise measurement. It is simply wide enough to fit the I beams, and long enough to provide support so that the bench doesn't rock side to side. It's roughly 7 inches longer than where the I-beams stop on each side. Make these measurements / tracings and then cut your plywood. Now drill and screw the plywood onto the frame, no wood glue needed. Do you best to put your screws in spots that don't already have screws in them. I trust you can use your eyes to figure that out.

For the top piece we are putting another layer of plywood. The shape of it is just an outline of the shape of the frame from the top. It's a T shape. The width of the bench is something you could vary depending on your preferences. Standard dimensions for powerlifting benches tends to be around 12 inches. I know some bigger lifters that like a much wider bench. I originally had mine wide like this, but it interfered with arms in the bottom position. My body type/size requires a smaller width, and since I'm not a competitive powerlifter, nobody will care if I make mine suited to my needs. But if you need/like a wider one than adjust accordingly.

As such, the trunk of the "T" on my bench is 9 1/2 inches wide. The top of the T is 15 1/2 by 5 inches (see picture). Cut this shape out of ply wood and screw it into the frame, again choosing places that don't already have screws in them. Also notice that i rounded the corners of this piece. I recommend you do the same to avoid potential injuries. Simply chop off the corner with a saw and then use sandpaper to round it out.

|

| Can also be used as a diving board. |

Before we upholster it, we have one last thing to do. We have to make the actual pad that you will lay on. This is composed of three parts, a plywood base, foam, and fabric. Start with the plywood base. I made mine roughly 10 inches wide. Some bigger guys like a wider pad. I'm a small guy, by my standards, and I originally had my pad wider but it was interfering with my arms at the low point of the lift. 10 inches works well for me. I can't say it will be the right size for you.

After you decide on a pad size, cut a rectangle of plywood measuring the width that you've decided on and a length that is about 2 inches longer than the top plywood piece of your frame. Measure, mark, and cut this piece out. Again, round the corners so that they don't rip the fabric you will cover it with.

Now we need to drill holes through both this newly cut plywood and the top plywood part of the frame. Center your plywood pad base on top of the plywood board on the frame so that it hands over an equal amount on all sides. Drill four holes, two towards the head of the bench and two towards the foot. The size of your holes should be just big enough to fit the shaft of your elevator bolts. The exact location of these is up to you to discover. You need the holes go through both pieces of plywood. You need them to be in open areas so that the frame doesn't interfere. These holes are where your elevator bolts and wignuts will be going so you need enough open space for your wingnut to thread on to the bolt.

|

| Notice how there's plenty of room to turn the wingnuts. Choose such places when drilling your holes. |

The next step is to secure your elevator bolts to the pad's plywood base. With the plywood base still centered on the frame, put your bolts into the holes. If you made your holes small enough the bolts won't sit all the way down. Elevator bolts have a slightly bigger square section towards the head. Put some Gorilla glue around the top of your bolt and hole. Now hammer the bolt into the hole. Repeat for all the bolts. Your elevator bolts need to be a minimum of 1 1/2 inches. They have to go through two pieces of 3/8" thick plywood, and have enough left over for a wingnut, which is like 1/4" at least. I personally got by with the absolute minimum bolt, it just barely fits. Apparently when I did this I miscalculated. I suggest you don't do the same. Get a longer bolt, if you can manage it, better too long than too short.

|

| These bolts are barely long enough to work. Do as I say, not as I do. |

The reason why we are doing all this is so that the pad section is removable. If you ever want to reupholster it, now you can. And we also don't want to fasten the pad by screwing up from the bottom because then we'd be getting stabbed by screws when we lie on it. You can also see why we choose something unorthodox like elevator bolts. They have a completely flat head, like a nail. So they won't create an uncomfortable bump in your pad like a rounded or hex bolt may.

The final step is to upholster this baby. You can choose whatever foam and fabric you want. Ideally heavy duty foam made for furniture or auto seats would be best. It's probably pretty expensive. I simply used a basic roll of foam that you can get at Walmart for like $15. For fabric, again upholstery fabric intended for furniture or auto seats will be of the highest quality but is more expensive. I used cheap vinyl from Walmart. It's holding up perfectly fine after six months of training. If it ever wears out I'll upgrade to better stuff. Depending on the width of your chosen fabric, you will either need one or two yards.

First we need to put the foam onto the plywood. If you are using thin and / or soft foam you should double or triple layer it. The foam should be just a bit larger than the dimensions of your plywood. Cut down your foam to match the size of your plywood. Lay your fabric out on the floor, so that the good side is facing down. Now lay your plywood with foam piece foam side down. So on the floor you will have your fabric, then foam layers, then plywood on top.

|

| Look at this quality craftsmanship. Good thing you can't see the it when it's on the bench. |

To secure the fabric to your plywood, we're going to use staples. I used T-50 size staples. Start with one of the long ends of your bench. Fold the edge of the fabric back over on itself about one inch. So that the edge of your fabric is now double thickness. This is the area we're going to staple into, the double thickness ensuring that it won't rip. Put the edge of this fabric onto the top of your plywood. Now begin stapling this edge. Press down hard with your staple gun and start from the middle and work outward. Doing this will allow you to smooth any wrinkles as you go. For the first edge it's not too important because none of the other edges are secured down yet. Staple all along this edge, leave the corners for later, we'll do them at the end.

Ideally, we don't want our pad to be to cushy. We want it to be firm. If you have cushy foam (as most cheap foam is, then we want to compress it by making the fabric sit tight around it. In order to do this, we have to compress the foam by standing on it as you staple. The second side you staple should be the long edge opposite the first side. You don't work around right to left or left to right. When you upholster something like this you work one side, then opposite side. This is the best way to ensure you can keep wrinkles out of the material.

Pull the material as tight as you can. Now trim it down to a size that will fit your bench. Don't trim too much off or it won't fit, but you likely have feet of excess because this bench is not very wide. After you trim it, fold the excess back on itself, just like you did with the first side. Stand on the plywood to compress the foam. Pull everything as tight as you can and begin stapling this edge, again starting from the middle and working out.

Repeat the procedure for the remaining two short ends. Now for the corners. There's no science to this, as far as I know. It's like wrapping a present. It comes out different every time you do it, And it usually looks kinda sloppy. But in the end it gets the job done. That pretty much describes my experience with both gift wrapping and upholstering corners. You'll have to trim some excess material off and probably fold some material in and tuck some things under. Just get it flat enough to put some staples in and it'll be fine.

By my standards, I did quite a sloppy job with the upholstery on this project. But luckily, when it's bolted to the frame the underside is completely hidden. So don't stress out trying to get things perfect, it really doesn't matter. What's important is that your pad is nice and tight and firm.

With the pad done, all that is left is to secure the pad to the frame. Line up your elevator bolts with the holes on your frame and drop it in. Take your wingnuts and hand tighten them onto your bolts. If you choose to paint your bench, do so without the padding on.

|

| Everything you see here for less than $150. I'm assuming you can't see the bar, weights, shoes, and everything else in the back corner. |

Now you have a bench that is stronger than you'll ever need it to be. You have the strength and function of an expensive bench and you paid only $50 or less for it. What would you get for $50 if you tried to buy a commercial bench? Something that could barely handle the weight that even a total noob will bench press in a few weeks time. This is the kind of project that makes you love DIY. It's definitely a better way to spend a Saturday than watching TV. Or you could put a TV in the garage and watch while you work.

This was another massive post. If you are unclear about anything please leave a comment and I'll do my best to help you out.

- Carl